Email Address

slavkasknonprofit@gmail.com

slavkaskno@slavkask.com

Phone Number

+421 914 704 008

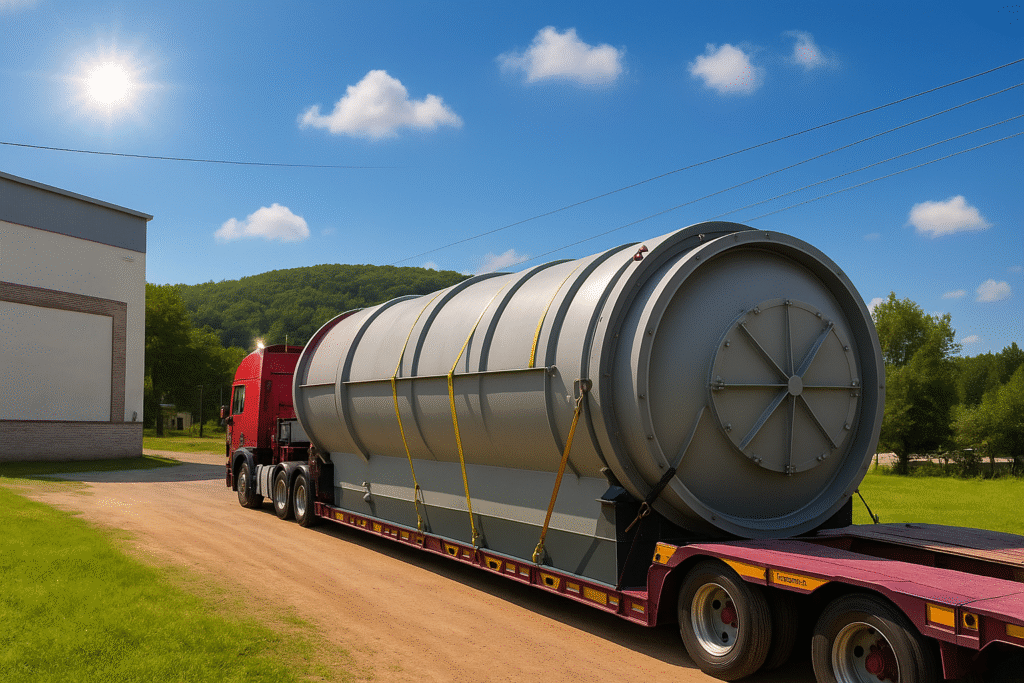

The IGNA Project, initiated by SlavkaSk n.o., has reached a major milestone. In early September, the first pyrolysis unit arrived in Koper, Slovenia, before being transported to Hungary, where preparations for installation were already complete.

In the last week of September, the final and most important component — the reactor — also arrived. This core part of the system will process around nine tons of plastic waste every day, converting it into 7,000 liters of oil by heating the material to 300°C.

This delivery marks more than just progress in logistics — it’s the moment when vision turns into reality. What was once only a plan on paper is now taking physical shape. Soon, what used to be piles of plastic waste will become a valuable source of energy.

Plastic pollution is one of the defining environmental challenges of our time. Hundreds of millions of tons of plastic are produced every year, yet only a small portion is effectively recycled. The rest ends up in landfills, is burned, or finds its way into the oceans. Traditional recycling methods can’t keep up — many plastics lose quality after just a few cycles, while demand for single-use materials keeps rising.

Pyrolysis offers a breakthrough. Instead of trying to recycle plastic in the traditional sense, it transforms it into valuable raw materials. In an oxygen-free environment, plastic is heated until it breaks down into oil, carbon black, and gas. Even the gas produced can be reused to power the system itself, making the process energy efficient and sustainable.

Unlike incineration, which simply destroys waste, pyrolysis recovers value — turning a problem into a resource.

The technology itself is impressive, but IGNA stands out because of its broader vision. Alongside the pyrolysis facilities, the project integrates a cryptocurrency-based financial model that ensures transparent funding, community engagement, and sustainable reinvestment for future growth.

By combining clean technology with decentralized finance, IGNA is creating a system where environmental and economic goals reinforce each other. It’s not just about processing waste — it’s about building a new kind of circular economy where sustainability and profitability can go hand in hand.

With the first pyrolysis facility now in Hungary, the next steps are installation and testing. Once the system becomes operational, it will serve as a proof of concept, demonstrating to communities, partners, and investors that the model works in practice — efficiently and sustainably.

The long-term goal is even more ambitious: to establish a global network of pyrolysis plants, each turning local plastic waste into local energy. This decentralized approach reduces transport costs, creates jobs, and helps communities experience the direct benefits of tackling the plastic crisis at its source.

The arrival of the first IGNA pyrolysis plant in Europe marks the beginning of a new chapter — one where innovation meets action. By merging advanced environmental technology with a forward-thinking financial system, IGNA proves that plastic waste doesn’t have to be a burden. It can be transformed into value — showing that environmental responsibility and economic opportunity can truly go hand in hand.